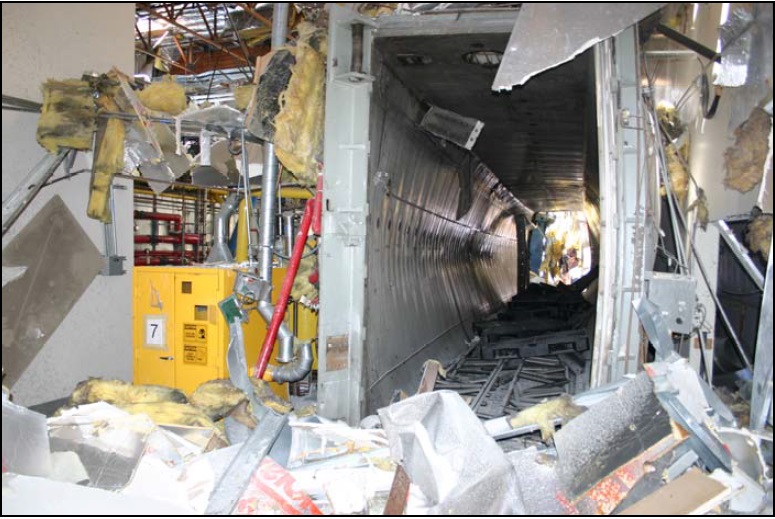

In August 2004, an explosion at Sterigenics International, California, injured four workers and caused significant damage.

The explosion that shut down the factory for 9 months and caused the evacuation of neighbors was caused by the reaction of ethylene oxide (EO) with oxygen.

Sterigenics is a company operating in the field of medical instruments, its sterilization being part of the current activity of any such producer.

Ethylene oxide (ethylene oxide) is used as an intermediate in the production of other chemicals and is also the most used sterilizing agent for medical materials: bandages, sutures, surgical implants.

Its advantages are low working temperature and compatibility with a variety of materials, the disadvantages are that it is toxic and flammable. The sterilization process involves the inclusion of medical instrumentation boxes in a stainless steel enclosure where EO is injected which destroys microbes and other germs, according to industry standards and regulatory regulations.

After the sterilization has been completed within a few hours, EO is removed from the sterilization chamber, and the process safety also involves a gas purge, typically nitrogen, to reduce the EO concentration in the enclosure.

In Sterigenics, on August 19, 2004, the process control system reported an error during a sterilization cycle at one of the eight sterilization chambers. The maintenance technician performed several system checks to determine if the alarm was correct but did not identify any problem and, with the superior’s approval, canceled the sterilization cycle.

After removing the instrument boxes from the sterilization chamber, several EO injection simulations were discontinued (as before) in order to identify a possible alarm.

With the desire to resume the technological process as quickly as possible, the technician asked the superior not to carry out the gas purge, relying on the idea that it was not a medical instrument in the enclosure, the last simulations performed removed the ethylene oxide from the enclosure and therefore no further washing with nitrogen was justified.

After closing the doors, within a few minutes, the ethylene oxide remaining in the sterilization chamber entered the ventilation system and, by reaction with oxygen, triggered the combustion.

- the alarm system of the sterilization enclosure could not warn about the reaction of ethylene oxide with oxygen;

- the company’s management did not implement the recommendations of the regulatory authorities on the monitoring of the sterilization enclosure;

- the employees involved in the process supervision were not sufficiently trained on the potential danger of the process.

Nitrogen purging in the sterilization chamber is a vital step in the safety of the process, and an oxygen level monitoring system in the sterilization chamber assures the safety of the plant.

In the case of Sterigenics, no such system has been implemented!

The US Chemical Safety Board investigation illustrates broadly the causes and factors that favored the incident