Laser cutting, welding, laser sintering, polymers termoblow, plasma cutting, hardening – are several treatment processes of materials in which nitrogen is used to reduce finishing work.

The result: reduction of production costs!

Laser cutting

Nitrogen does not react with the material during cutting and is the most common gas used in cutting high-alloy steels and stainless steels. Thus, any phenomenon of oxidation is removed and is the basis of maintaining anti-corrosion properties of parts cut, ensuring a good adhesion of the paint to the cut edges.

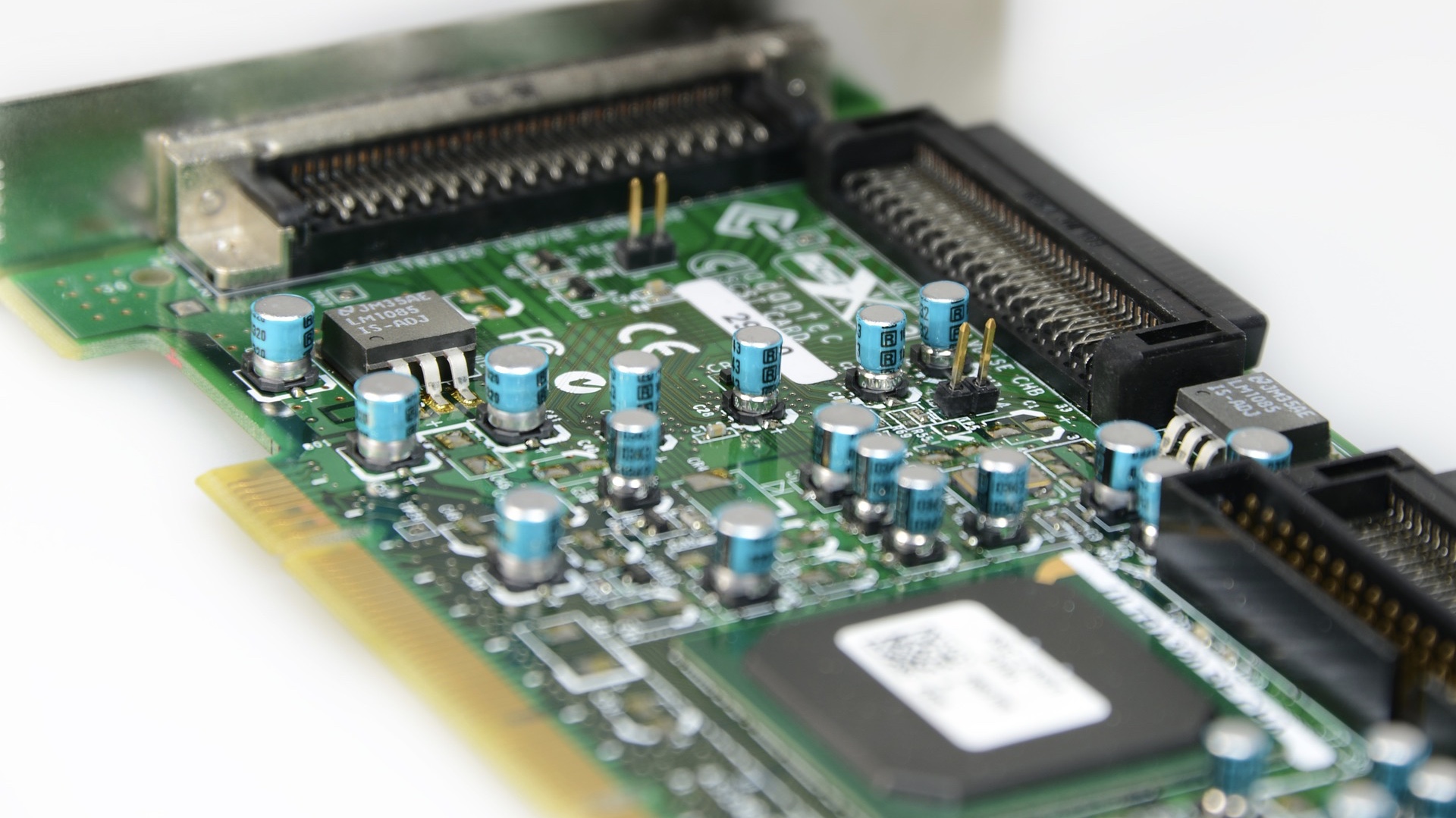

Welding

Nitrogen is used mainly for welding inert electronic circuit boards. Welding in an inert atmosphere improves assembly quality while reducing sensitivity to process fluctuations.

Laser Sintering

Selective laser sintering is a manufacturing process in the form of free powders of the components by sintering. This process is better known as rapid prototyping. In the sintering chamber is maintained an atmosphere of nitrogen that prevents explosions during processing large amounts of powder.

Plasma cutting

Plasma is an ionized form of gas. In plasma cutting, the nitrogen is sent under pressure through a torch which moves in the spiral form, exits through a narrow orifice and passes through an electric arc which ionizes the gas.

Tempering

Tempering involves heating the components at a temperature above the transformation temperature of the material and then bathing in oil or molten salt. It aims to obtain a structure with high hardness martensitic or bainitic. Tempering may be performed in a variety of furnace, requiring a protective atmosphere to prevent oxidation and decarburization during the process.

- Controlled operating costs

- Continuously monitored process

- Competitive advantage through operational efficiency