Resourcefulness – is OMV Petrom sustainability strategy for responsible business behavior.

Environmental management is part of this strategy. Due to its specific activity, OMV Petrom assumes a special responsibility to manage the environmental impact and to ensure safe and effective operations.

Exploration and production activities are, by their nature, operations with impact over the environment.

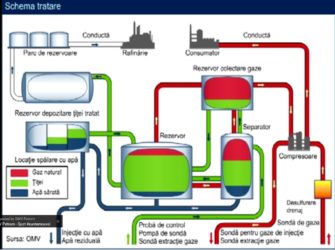

Such an operation is explained by Petrom specialists in the treatment scheme below – video by OMV Petrom.

Before transporting oil and gas in order to process them, they are treated on site, by removing the sand and water. If oil and gas are extracted together, their separation takes place.

Tanks are a constant presence in the oil exploration and production processes for different types of substances, and their protection is essential in process safety.

Corbii Mari Park was the first park aligned with European legislation and national environmental protection regarding the use of processing facilities to eliminate air emissions of associated gas extraction and processing of crude oil.

Corbii Mari modernization project included the usage of a closed water tank reservoir, with a nitrogen blanket – blanketing system.

The solution was implemented also to modernization of Silistea – Scurtu Mare park: blanketing system with NitroFil® nitrogen generator for process water tank against corrosion. Nitrogen is also used as a source of dry gas for pneumatic systems.

Advantages of using a nitrogen generator versus bottles is highlighted in supply and handling costs.

Another advantage is that nitrogen can be used for inerting pipes in order to carry out maintenance operations.

Installation benefits are found in protecting the equipment from corrosion.Aurelian DRAGHICIU – OMV Petrom

Team Leader Operations Readiness & Assurance, Upstream, Asset IV Moesia